Comparing EV Battery Cooling Systems

An analysis of different electric vehicle battery cooling systems and their effectiveness.

Comparing EV Battery Cooling Systems: Keeping Your EV Running Cool and Efficient

Hey EV enthusiasts! Ever wondered what keeps your electric vehicle's battery from overheating, especially during those long drives or fast charging sessions? It's all thanks to sophisticated battery cooling systems. Just like your body needs to regulate its temperature, EV batteries perform best within a specific temperature range. Too hot, and you risk degradation and reduced performance; too cold, and efficiency drops. Today, we're diving deep into the various types of EV battery cooling systems, how they work, and which ones are leading the pack. We'll also look at some specific examples, their real-world applications, and even touch on their impact on cost and performance.

Why EV Battery Cooling Matters: Performance and Longevity

Before we get into the 'how,' let's quickly cover the 'why.' Electric vehicle batteries, primarily lithium-ion, generate heat during charging and discharging cycles. This heat, if not managed, can lead to several problems:

- Reduced Performance: Overheated batteries can't deliver their full power output, meaning slower acceleration and reduced top speed.

- Accelerated Degradation: High temperatures significantly speed up the chemical reactions that cause battery degradation, shortening its lifespan.

- Safety Concerns: In extreme cases, uncontrolled thermal runaway can lead to fires, though modern EVs have multiple safety layers to prevent this.

- Charging Speed Limitations: To protect the battery, the vehicle's Battery Management System (BMS) will often limit charging speeds if the battery temperature is too high or too low.

Conversely, in cold weather, batteries also need to be warmed up to operate efficiently and accept fast charging. This is where sophisticated thermal management systems come into play, ensuring the battery stays in its optimal temperature window, regardless of external conditions or driving demands.

Types of EV Battery Cooling Systems: Air, Liquid, and Refrigerant

There are generally three main types of battery cooling systems used in electric vehicles, each with its own advantages and disadvantages:

1. Air Cooling Systems: Simplicity and Cost-Effectiveness for EV Batteries

Air cooling is the simplest and often the most cost-effective method. It works by circulating ambient air, or sometimes conditioned air from the cabin's HVAC system, over the battery cells to dissipate heat. Think of it like a fan blowing over a hot object.

How Air Cooling Works for EV Batteries: Passive vs. Active

- Passive Air Cooling: This relies on natural convection or airflow generated by the vehicle's movement. It's the least effective and typically found in smaller, lower-performance EVs or hybrids where heat generation is minimal.

- Active Air Cooling: This uses fans to force air over the battery pack. Some systems might even draw air from the cabin's air conditioning system to provide cooler air to the battery.

Pros and Cons of Air Cooled EV Batteries: Efficiency and Limitations

- Pros: Simple design, lower manufacturing cost, lighter weight, fewer components (less to break).

- Cons: Less effective at precise temperature control, especially under heavy loads or in extreme climates. Can struggle to cool batteries during fast charging. Not ideal for high-performance or long-range EVs.

EV Models Using Air Cooling: Nissan Leaf and Mitsubishi i-MiEV

A prime example of an EV that historically used air cooling is the Nissan Leaf (first and second generation up to 2023 models). While it kept costs down, many owners in hot climates reported significant battery degradation over time, often referred to as 'Rapidgate' due to reduced fast charging speeds after multiple DC fast charges. The Mitsubishi i-MiEV also utilized air cooling. These vehicles are generally more suited for urban driving and moderate climates where battery stress is lower.

2. Liquid Cooling Systems: Precision and Performance for EV Batteries

Liquid cooling is the most common and effective method for modern electric vehicles, especially those designed for performance, long range, and fast charging. It involves circulating a coolant (usually a mixture of water and glycol, similar to engine coolant) through channels or plates that are in direct contact with or very close to the battery cells.

How Liquid Cooling Works for EV Batteries: Direct vs. Indirect Contact

- Indirect Liquid Cooling: The coolant flows through a cold plate or channels that are thermally coupled to the battery modules or cells. The heat transfers from the cells to the cold plate, and then to the coolant. This is the most common setup.

- Direct Liquid Cooling (Dielectric Fluid): In more advanced systems, the battery cells are submerged directly in a non-conductive dielectric fluid. This offers superior heat transfer but requires specialized fluids and sealing.

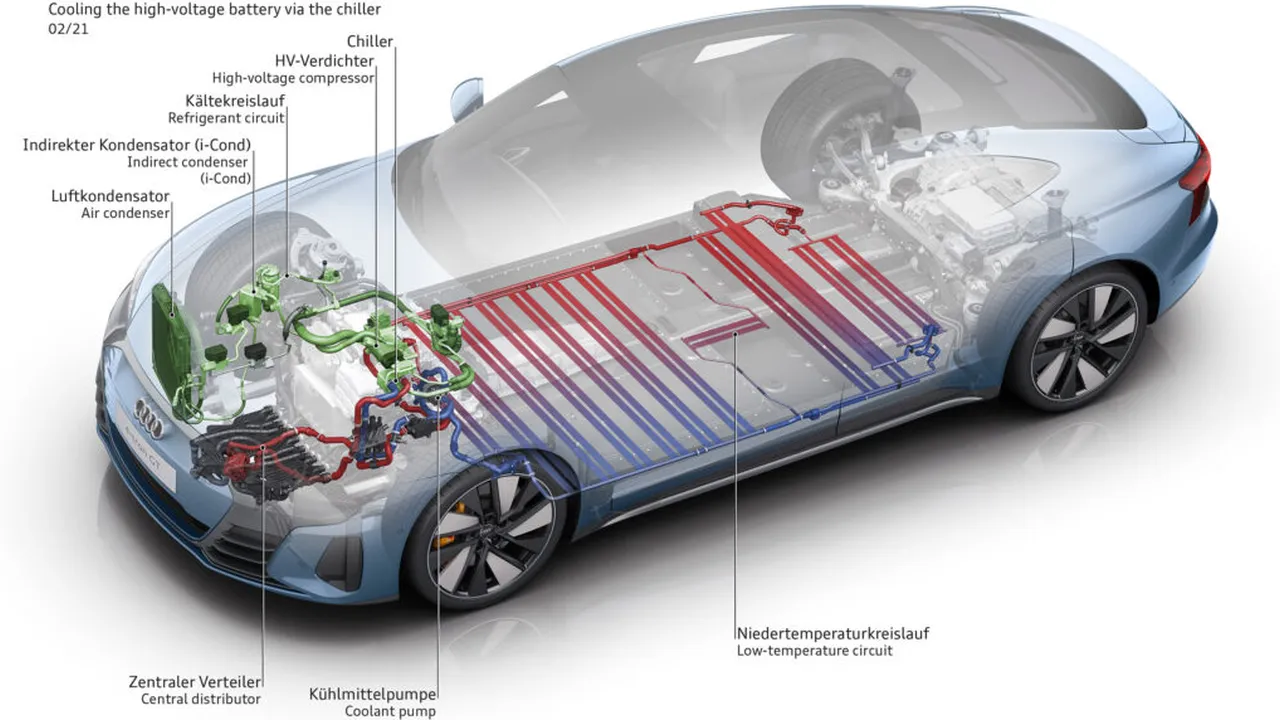

Components of a Liquid Cooled EV Battery System: Pumps, Radiators, and Chillers

A typical liquid cooling system includes:

- Coolant Pump: Circulates the coolant through the system.

- Cold Plates/Channels: Integrated within or around the battery pack to absorb heat.

- Radiator: Dissipates heat from the coolant to the ambient air.

- Chiller/Heater: Often integrated with the vehicle's HVAC system, allowing the coolant to be actively cooled (using the AC compressor) or heated (using a PTC heater or heat pump) to maintain precise battery temperature.

- Reservoir and Hoses: To hold and transport the coolant.

Pros and Cons of Liquid Cooled EV Batteries: Optimal Thermal Management

- Pros: Excellent temperature control, even under heavy loads and fast charging. Extends battery lifespan and maintains performance. Allows for higher power output and faster charging speeds.

- Cons: More complex system, higher manufacturing cost, heavier, more components (potential for leaks or failures).

EV Models Using Liquid Cooling: Tesla, Hyundai Ioniq 5, Ford Mustang Mach-E

Virtually all high-performance and long-range EVs today use liquid cooling. Examples include:

- Tesla Model 3/Y/S/X: Tesla's sophisticated liquid cooling system, often integrated with a heat pump, is a key reason for their excellent fast charging capabilities and battery longevity. Their 'snake' cooling channels are particularly innovative.

- Hyundai Ioniq 5 / Kia EV6: These vehicles utilize a highly effective liquid cooling system that allows for incredibly fast 800V charging. Their E-GMP platform is designed from the ground up with advanced thermal management.

- Ford Mustang Mach-E: Ford's liquid cooling system ensures consistent performance and charging, even during spirited driving.

- Porsche Taycan: Known for its track-ready performance, the Taycan employs a highly advanced liquid cooling system to manage the immense heat generated during high-power discharges and rapid charging.

3. Refrigerant Cooling Systems: Direct Expansion for EV Batteries

While often grouped under 'liquid cooling,' some systems use the vehicle's air conditioning refrigerant directly to cool the battery. This is known as direct expansion cooling.

How Refrigerant Cooling Works for EV Batteries: Direct Heat Exchange

Instead of using a secondary coolant loop, the refrigerant from the AC system flows directly through cold plates or channels within the battery pack. As the refrigerant expands and evaporates, it absorbs heat from the battery, similar to how an air conditioner cools a room.

Pros and Cons of Refrigerant Cooled EV Batteries: Efficiency and Integration

- Pros: Highly efficient heat transfer, can provide very precise temperature control, often simpler integration with the existing HVAC system.

- Cons: Requires specialized components for handling refrigerant within the battery pack, potential for refrigerant leaks, and the system's primary function (cabin cooling) might be impacted if the battery demands significant cooling.

EV Models Using Refrigerant Cooling: Chevrolet Bolt EV and BMW i3

The Chevrolet Bolt EV is a notable example that uses a direct refrigerant cooling system for its battery. This system has proven effective in managing battery temperatures, contributing to the Bolt's respectable range and charging performance for its class. The BMW i3 also utilized a similar approach, integrating battery cooling with its climate control system.

Advanced Thermal Management Strategies: Heat Pumps and Integrated Systems for EV Batteries

Modern EVs are moving towards even more sophisticated thermal management. Many now incorporate heat pumps, which can efficiently heat or cool the battery (and cabin) by transferring heat rather than generating it. This significantly improves efficiency, especially in cold weather, by pre-conditioning the battery for optimal performance and charging.

Integrated thermal management systems are also becoming standard. These systems manage the temperature of not just the battery, but also the electric motors, power electronics, and even the cabin, all through a single, interconnected loop. This allows for highly efficient heat transfer and recovery, further boosting overall vehicle efficiency and performance.

Choosing the Right EV: Battery Cooling System Considerations for Buyers

When you're looking at buying an EV, especially a used one, understanding its battery cooling system can be crucial. Here's what to consider:

- Driving Habits: If you plan on frequent fast charging, long road trips, or live in a hot climate, a liquid-cooled EV is almost a necessity for battery longevity and consistent performance.

- Climate: Extreme hot or cold climates put more stress on batteries. Advanced liquid cooling with heat pump integration is ideal for these conditions.

- Performance Needs: High-performance EVs (like Teslas, Porsche Taycan, Lucid Air) rely heavily on robust liquid cooling to deliver their advertised power and acceleration repeatedly.

- Budget: Air-cooled EVs tend to be cheaper upfront, but you might pay more in the long run due to potential battery degradation or reduced resale value.

Specific Product Recommendations and Use Cases: Best EV Battery Cooling in Action

Let's look at some specific examples and how their cooling systems benefit different users:

1. Tesla Model 3/Y: Integrated Liquid Cooling for Everyday Performance and Fast Charging

Cooling System: Advanced liquid cooling with integrated heat pump (newer models). Tesla's patented 'snake' cooling channels wrap around individual battery cells, providing excellent thermal contact. The system is highly integrated, managing the temperature of the battery, motors, and cabin.

Use Case: Ideal for daily commuting, long road trips, and frequent Supercharging. The robust cooling system ensures consistent performance and minimal degradation, even with aggressive driving or repeated fast charging. This is why Teslas maintain good range and power output over many years.

Benefit: Superior battery longevity, consistent fast charging speeds, and reliable performance in varied climates. The heat pump further enhances efficiency in cold weather.

Approximate Price Range (New): $38,000 - $55,000 (Model 3), $45,000 - $60,000 (Model Y).

2. Hyundai Ioniq 5 / Kia EV6: 800V Architecture and Optimized Liquid Cooling for Ultra-Fast Charging

Cooling System: Highly optimized liquid cooling system designed for their 800V E-GMP platform. This system is specifically engineered to handle the immense heat generated during ultra-fast DC charging (up to 350 kW).

Use Case: Perfect for drivers who prioritize rapid charging on road trips and want minimal downtime. The cooling system allows these vehicles to charge from 10% to 80% in as little as 18 minutes under ideal conditions.

Benefit: Unmatched charging speeds among mainstream EVs, excellent thermal stability, and consistent performance. The pre-conditioning feature warms the battery before arriving at a fast charger.

Approximate Price Range (New): $42,000 - $58,000 (Ioniq 5), $43,000 - $62,000 (EV6).

3. Porsche Taycan: Performance-Oriented Liquid Cooling for Track Days and High Demands

Cooling System: Extremely sophisticated and robust liquid cooling system, designed to handle sustained high-power output and repeated acceleration runs without thermal throttling. It features multiple cooling circuits and precise temperature management.

Use Case: For performance enthusiasts who want to push their EV to its limits, whether on a track or during spirited driving. The cooling system ensures the battery and motors remain within optimal temperatures, preventing power reduction.

Benefit: Sustained peak performance, exceptional thermal resilience, and the ability to handle repeated high-demand scenarios without overheating.

Approximate Price Range (New): $90,000 - $190,000+.

4. Chevrolet Bolt EV: Direct Refrigerant Cooling for Compact Efficiency

Cooling System: Direct refrigerant cooling, where the AC system's refrigerant directly cools the battery pack. This is a more compact and efficient design for smaller vehicles.

Use Case: Excellent for urban and suburban commuting, offering good range and consistent performance in a more affordable package. While not designed for ultra-fast charging marathons, it handles typical DC fast charging sessions well.

Benefit: Effective temperature management in a smaller footprint, contributing to the Bolt's overall efficiency and range for its size. It's a good balance of cost and performance for its segment.

Approximate Price Range (New): $27,000 - $32,000 (Bolt EV/EUV).

5. Nissan Leaf (Older Generations): Air Cooling for Budget-Conscious Buyers (with caveats)

Cooling System: Primarily passive or active air cooling (depending on generation and specific model year). No liquid cooling for the battery.

Use Case: Best suited for drivers in moderate climates with short commutes and infrequent fast charging needs. If you primarily charge at home overnight and don't push the car hard, it can be a very affordable entry into EV ownership.

Benefit: Lower upfront cost, simpler maintenance (fewer components). However, be aware of potential battery degradation issues in hot climates or with heavy fast charging use.

Approximate Price Range (Used): $8,000 - $20,000 (depending on year, mileage, and battery health).

The Future of EV Battery Thermal Management: Beyond Current Systems

The evolution of EV battery cooling isn't stopping here. We're seeing continuous innovation:

- Immersion Cooling: Submerging battery cells directly in a dielectric fluid offers superior heat transfer and could enable even faster charging and higher power densities. Companies like StoreDot are exploring this for extreme fast charging.

- Phase Change Materials (PCMs): These materials can absorb and release large amounts of latent heat as they change phase (e.g., from solid to liquid), providing passive thermal buffering for batteries.

- AI-Driven Thermal Management: Using artificial intelligence to predict driving patterns, charging needs, and environmental conditions to proactively optimize battery temperature, maximizing efficiency and lifespan.

- Integrated Chassis Cooling: Utilizing the vehicle's chassis or structural components as part of the cooling system, further optimizing space and weight.

Ultimately, the choice of battery cooling system significantly impacts an EV's performance, longevity, and charging capabilities. As battery technology continues to advance, so too will the sophistication of these vital thermal management systems, ensuring that electric vehicles remain efficient, powerful, and reliable for years to come.

:max_bytes(150000):strip_icc()/277019-baked-pork-chops-with-cream-of-mushroom-soup-DDMFS-beauty-4x3-BG-7505-5762b731cf30447d9cbbbbbf387beafa.jpg)