EV Battery Recycling Programs and Initiatives

Information on electric vehicle battery recycling programs and their environmental benefits.

EV Battery Recycling Programs and Initiatives

The Urgent Need for EV Battery Recycling and Sustainability

The rapid adoption of electric vehicles is a crucial step towards decarbonizing transportation. However, this transition brings with it a significant challenge: managing the vast quantities of EV batteries reaching their end-of-life. These batteries, primarily lithium-ion, contain valuable and often rare earth materials like cobalt, nickel, and lithium. Disposing of them in landfills is not only environmentally irresponsible due to potential leaching of hazardous materials but also represents a massive loss of valuable resources. Recycling these batteries is essential for several reasons:

- Resource Conservation: Recovering critical materials reduces the need for new mining, which is often environmentally destructive and resource-intensive.

- Environmental Protection: Proper recycling prevents hazardous chemicals from contaminating soil and water.

- Supply Chain Security: Recycling can reduce reliance on volatile global supply chains for raw materials, enhancing energy independence.

- Economic Opportunity: A robust recycling industry creates jobs and fosters innovation in material science and engineering.

Global EV Battery Recycling Initiatives and Key Players

Across the globe, various governments, manufacturers, and specialized companies are launching initiatives to tackle EV battery recycling. It's a complex ecosystem, but here are some of the major players and their approaches:

North American EV Battery Recycling Efforts and Companies

In North America, the focus is on building a domestic recycling infrastructure to support the growing EV market. Several companies are leading the charge:

- Redwood Materials: Founded by Tesla co-founder JB Straubel, Redwood Materials is a prominent player aiming for a closed-loop battery supply chain. They partner with major automakers like Ford and Volvo to collect end-of-life batteries and manufacturing scrap. Their process focuses on hydrometallurgy to recover high-purity materials. They're building large-scale facilities in Nevada and South Carolina.

- Li-Cycle: Li-Cycle employs a 'Spoke & Hub' model. Their 'Spokes' (smaller facilities) shred batteries to produce 'black mass,' a concentrated form of valuable materials. This black mass is then processed at their 'Hubs' (larger facilities) using hydrometallurgy to extract individual metals. They have operations in North America and Europe.

- Cirba Solutions: With a long history in battery recycling, Cirba Solutions offers comprehensive solutions for various battery chemistries, including EV batteries. They focus on safe collection, transportation, and processing.

- Ascend Elements: This company specializes in direct-to-cathode recycling, which aims to recover and re-manufacture cathode active materials directly from spent batteries, potentially reducing costs and energy consumption compared to traditional methods.

European EV Battery Recycling Regulations and Innovators

Europe has some of the most ambitious regulations for battery recycling, pushing for higher collection and recycling targets. The EU Battery Regulation, for instance, sets stringent requirements for battery design, collection, and recycling efficiency.

- Umicore: A Belgian multinational, Umicore is a pioneer in battery recycling, offering a comprehensive solution for various battery types, including EV batteries. They use pyrometallurgy and hydrometallurgy to recover valuable metals.

- Northvolt: While primarily a battery manufacturer, Swedish company Northvolt is also heavily invested in recycling. Their 'Revolt' program aims to establish a circular battery ecosystem, integrating recycling directly into their battery production process.

- BASF: The German chemical giant is investing in battery recycling technologies, particularly in hydrometallurgical processes to recover critical metals.

- Accurec: A German company specializing in lithium-ion battery recycling, focusing on efficient and environmentally friendly processes.

Asian EV Battery Recycling Landscape and Key Players

Asia, particularly China, is a major hub for EV battery manufacturing and is rapidly developing its recycling capabilities. South Korea and Japan are also significant players.

- GEM Co. Ltd. (China): One of the largest battery recycling companies in China, GEM processes a vast volume of batteries and aims to create a closed-loop industrial chain.

- Brunp Recycling (CATL Subsidiary, China): As a subsidiary of the world's largest EV battery manufacturer, CATL, Brunp Recycling plays a crucial role in managing end-of-life batteries from CATL's products, focusing on material recovery and reuse.

- SungEel Hi-Tech (South Korea): A leading South Korean company specializing in lithium-ion battery recycling, recovering valuable metals through hydrometallurgical processes.

- JFE Holdings (Japan): While a steel manufacturer, JFE is exploring battery recycling technologies, leveraging its expertise in material processing.

The EV Battery Recycling Process From Collection to Re-manufacturing

Recycling an EV battery is a multi-step process that requires specialized facilities and expertise. It's not as simple as throwing it in a bin. Here's a general overview:

Collection and Transportation of End-of-Life EV Batteries

The first critical step is safely collecting and transporting spent EV batteries. These batteries are heavy, contain residual energy, and can be hazardous if not handled correctly. Manufacturers, dealerships, and specialized recycling companies often have take-back programs. Proper packaging and transportation according to hazardous materials regulations are paramount.

Disassembly and Pre-treatment for Material Recovery

Once at the recycling facility, batteries undergo initial processing:

- Discharge: Any remaining energy in the battery is safely discharged to prevent hazards.

- Disassembly: Batteries are carefully disassembled into modules and individual cells. This can be done manually or increasingly with automated systems.

- Shredding/Crushing: The cells are then shredded or crushed to break them down into smaller pieces, often under inert atmospheres to prevent reactions. This process yields 'black mass,' a mixture of cathode and anode materials, binders, and other components.

Material Separation and Extraction Pyrometallurgy vs Hydrometallurgy

This is where the magic happens, separating the valuable metals. Two primary methods are used:

- Pyrometallurgy (Smelting): This involves using high heat to melt down the battery components. While effective at recovering metals like cobalt and nickel, it's energy-intensive and often doesn't recover lithium efficiently. It's a more established technology.

- Hydrometallurgy (Chemical Leaching): This method uses chemical solutions to dissolve the metals from the black mass. It's generally more energy-efficient and can recover a wider range of materials, including lithium, with higher purity. Many newer recycling facilities are adopting or developing advanced hydrometallurgical processes.

- Direct Recycling: An emerging technology that aims to preserve the cathode structure, allowing for direct re-manufacturing of new battery materials without breaking down the chemical compounds. This is potentially the most efficient and environmentally friendly method but is still largely in the R&D phase for commercial scale.

Refining and Re-manufacturing for New Battery Production

The recovered metals are then refined to high purity, making them suitable for use in new battery production. The goal is to create a circular economy where materials from old batteries feed directly into the manufacturing of new ones, reducing the need for virgin materials.

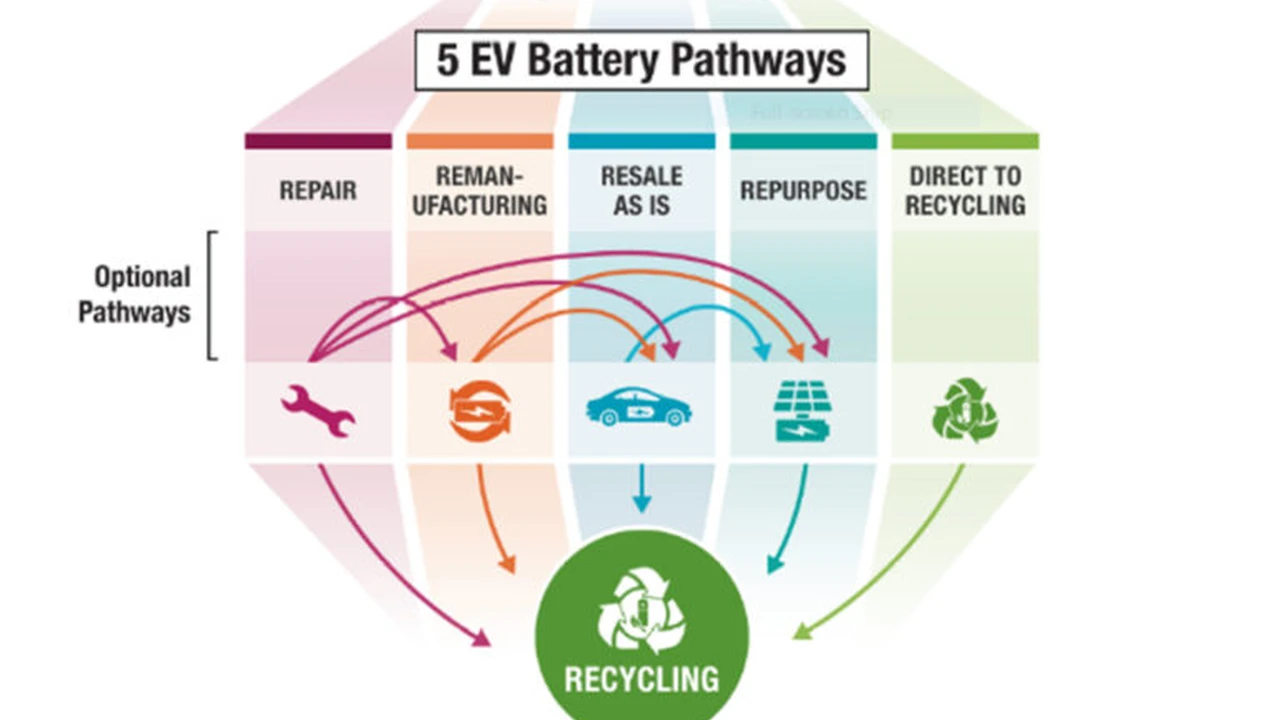

Second Life Applications for EV Batteries Extending Their Utility

Before full recycling, many EV batteries can have a 'second life' in less demanding applications. This extends their utility and further reduces environmental impact. Batteries typically retain 70-80% of their original capacity when they are no longer suitable for automotive use.

Energy Storage Systems for Homes and Grids

The most common second-life application is in stationary energy storage. These batteries can be repurposed for:

- Residential Energy Storage: Storing solar energy for home use, providing backup power during outages.

- Commercial and Industrial Storage: Peak shaving, demand charge management, and backup power for businesses.

- Grid-Scale Storage: Supporting renewable energy integration, grid stabilization, and ancillary services.

Example Products and Use Cases:

- Nissan's xStorage Home: Nissan, in partnership with Eaton, has developed home energy storage systems using repurposed Nissan LEAF batteries. These systems can store solar power or off-peak grid electricity, providing energy independence and reducing utility bills. Prices vary but typically range from $5,000 to $10,000+ depending on capacity and installation.

- Renault's Advanced Battery Storage (ABS) Project: Renault is involved in several projects using second-life EV batteries for large-scale energy storage, such as supporting renewable energy farms or providing grid services. These are typically large, custom installations with costs in the millions.

- B2U Storage Solutions (USA): This company specializes in repurposing EV batteries for grid-scale energy storage. They have projects in California using batteries from various manufacturers. Their solutions are tailored for utility companies and large commercial clients.

Other Innovative Second Life Applications and Pilot Programs

Beyond stationary storage, other innovative uses are being explored:

- Electric Forklifts and Material Handling Equipment: Less demanding power cycles make them suitable for industrial vehicles.

- Street Lights and Off-Grid Power Solutions: Providing reliable power in remote areas or for public infrastructure.

- Charging Stations: Some fast-charging stations use second-life batteries as buffers to reduce strain on the grid.

Challenges and Opportunities in EV Battery Recycling The Road Ahead

While significant progress has been made, the EV battery recycling industry faces several challenges:

Logistical Hurdles and Collection Infrastructure

Collecting and transporting batteries from diverse sources (individual owners, dealerships, scrapyards) across vast geographical areas is complex and costly. A robust, efficient, and safe collection infrastructure is still being developed.

Technological Advancements and Efficiency Improvements

Current recycling processes are improving but still have room for greater efficiency, higher material recovery rates, and reduced environmental footprints. Research into direct recycling and more sustainable chemical processes is ongoing.

Economic Viability and Market Dynamics

The profitability of battery recycling can fluctuate with the prices of raw materials. Ensuring economic viability for recyclers, especially as battery chemistries evolve, is crucial for sustained investment in the sector.

Policy and Regulatory Frameworks for a Circular Economy

Strong government policies, like extended producer responsibility (EPR) schemes and recycling targets, are vital to drive investment and ensure that batteries are indeed recycled. Harmonizing regulations across different regions can also streamline the process.

The Future of EV Battery Recycling A Sustainable Ecosystem

The future of EV battery recycling is bright, driven by technological innovation, increasing environmental awareness, and supportive policies. As the volume of end-of-life EV batteries grows, so too will the scale and sophistication of recycling operations. The ultimate goal is a truly circular economy for EV batteries, where valuable materials are continuously recovered and reused, minimizing waste and maximizing resource efficiency. This not only benefits the environment but also strengthens the global supply chain for electric vehicles, paving the way for a more sustainable and electrified future.

:max_bytes(150000):strip_icc()/277019-baked-pork-chops-with-cream-of-mushroom-soup-DDMFS-beauty-4x3-BG-7505-5762b731cf30447d9cbbbbbf387beafa.jpg)